In the era of renewable energy, Solar Farms and Solar Rooftops are sprouting up across industrial landscapes. However, many project owners overlook a critical aspect: the degrading “health” of their solar panels. A silent killer known as a “Hotspot” often goes undetected, reducing energy production and, in the worst-case scenario, becoming a primary cause of catastrophic fires.

This article explores what hotspots are, why they are dangerous, and why traditional manual inspections are no longer sufficient—making AI and Drone Inspection the new standard for safety and efficiency.

1. What is a Hotspot? And Why Should You Worry?

A Hotspot occurs when a specific solar cell within a panel malfunctions. Instead of generating electricity, it acts as a resistor, converting electrical energy into “heat.” This causes the temperature in that specific area to spike significantly compared to the rest of the panel.

What Causes Hotspots? Causes range from external factors to internal defects:

- Shading: Shadows from nearby trees, utility poles, or overgrown vegetation can block sunlight, causing the shaded cells to stop producing power and heat up.

- Soiling: Bird droppings, heavy dust accumulation, or stubborn water stains.

- Physical Damage: Micro-cracks caused by transportation, improper installation (e.g., over-tightening clamps), or impact from hail and stones.

- Component Failure: Internal malfunctions, such as defective Bypass Diodes.

The Risks: If left unchecked, accumulated heat can exceed 100°C, causing the backsheet to burn, glass to shatter, and potentially triggering a “fire” that spreads to the entire facility. Furthermore, a single hotspot can drag down the performance of an entire string, silently draining your revenue.

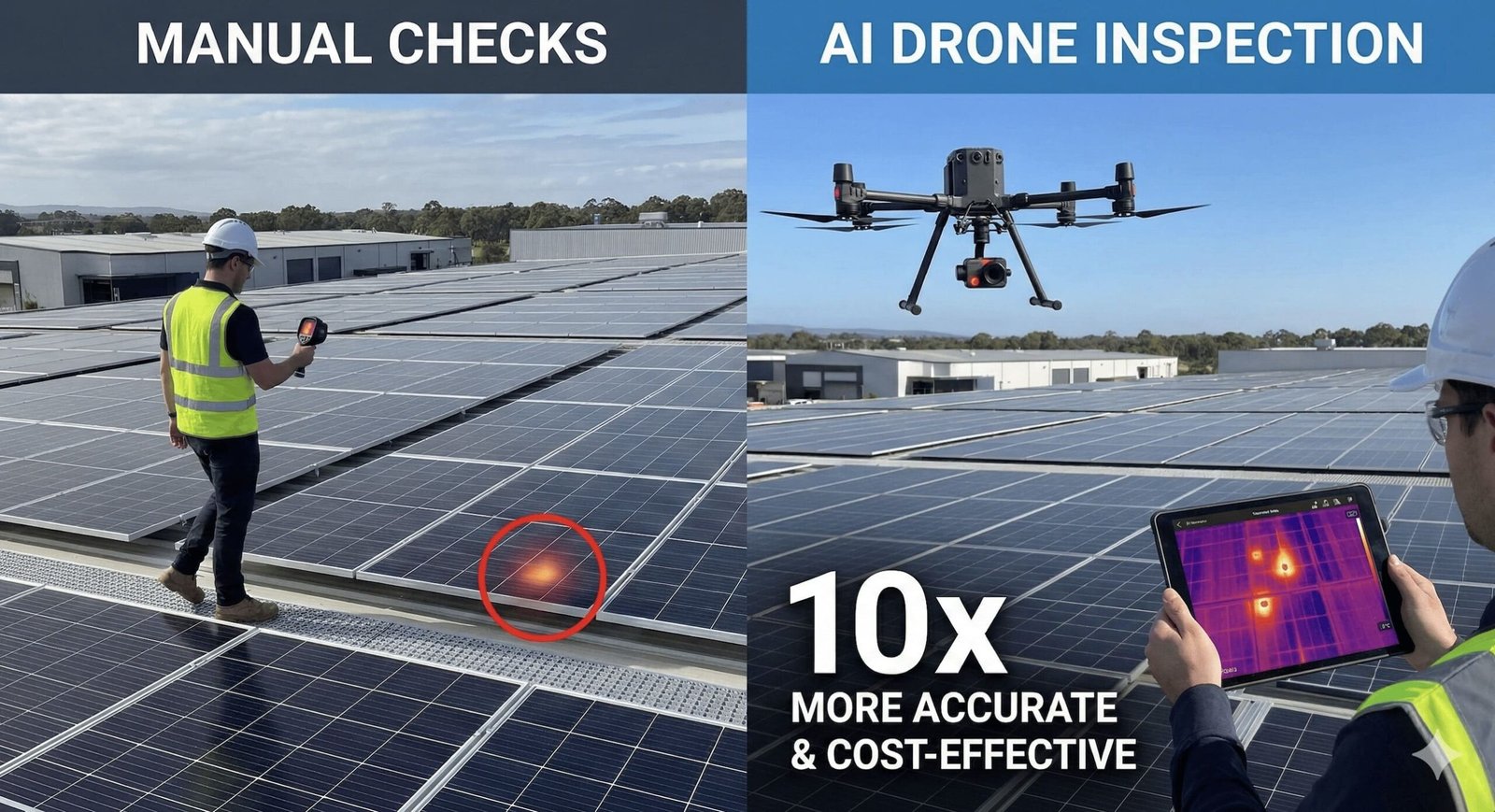

2. Why “Manual Inspection” is Obsolete

Traditionally, solar farm inspections rely on technicians walking through the site with handheld thermal cameras to spot-check panels. This method has severe limitations that put owners at a disadvantage:

- Slow and Inefficient: For large solar farms or factory roofs spanning tens of thousands of square meters, a manual inspection can take 3 to 7 days, resulting in high labor costs and significant downtime.

- Incomplete Data (Sampling Bias): Due to time constraints and fatigue, technicians often rely on “sampling”rather than checking every single panel. This leaves a high risk that critical hotspots will be missed.

- Low Accuracy & Human Error: Handheld cameras at eye level often miss defects due to poor viewing angles. Manual data recording is also prone to error—technicians may forget exactly which panel or row a specific photo belongs to.

- Safety Hazards: Walking on sloped roofs or navigating complex sites poses safety risks to personnel.

3. The Revolution: “AI & Drone Inspection” – Faster, sharper, Smarter

Modern O&M technology has overcome these barriers by combining Smart Drones equipped with dual cameras (High-resolution RGB + Thermal Imaging) and World-Class AI Software (such as Raptor Maps or Glint Solar). The difference is transformative:

1. From 7 Days to 1 Day (Speed & Efficiency) Drones can scan an entire solar farm or rooftop, achieving 100% coverage in less than 1 day. This drastically reduces inspection time compared to manual methods, delivering rapid results without the wait.

2. Precision at the “Serial Number” Level This is a game-changer. The AI system doesn’t just identify a problem zone; it pinpoints defects down to the “cell level.” By mapping GPS coordinates to the farm’s Digital Twin, the system identifies exactly which String, Module, and Serial Number is affected . Technicians can simply look at their tablets and walk directly to the faulty panel for immediate repair.

3. Deep Diagnosis Beyond the Human Eye Powered by Machine Learning trained on millions of images, the AI can classify defects with far greater detail than humans. It can distinguish whether the heat is caused by:

- Shading issues

- Soiling or bird droppings

- Diode failure or internal cracking This insight allows engineers to treat the “root cause” rather than just the symptoms.

4. Digital Twin Reporting (Asset Digitization) Gone are the days of thick paper reports. All drone data is processed in the cloud to create a Digital Twin of your power plant. Executives can log in to view the farm’s health in real-time, assess total damage, and track repair status on a single dashboard.

4. Tangible ROI (Return on Investment)

While high-tech solutions may seem costly, AI Drone Inspection actually “reduces costs” in the long run:

- Labor Savings: Eliminates the need for large teams walking the site for days.

- Recovered Yield: Detecting and fixing defects early can recover 2-5% of lost energy production annually, representing significant revenue for large-scale operations.

- Extended Lifespan: Addressing hotspots before they escalate protects the longevity of your assets.

The Choice for Industry Leaders

maintaining a solar power plant is no longer about “fixing it when it breaks”—it’s about “knowing before it fails” through precise technology.

At Queen Energy and Chanonda, we combine advanced engineering expertise with world-class AI Drone Inspectiontechnology. We are ready to safeguard your solar assets with the same standards used by industry giants like WHA, GULF, and B.GRIMM . Ensure that every ray of sunlight hitting your panels converts into profitable energy… not profit-burning heat.

Don’t wait for a fire or a spike in energy losses. Consult our experts to health-check your solar system today with the best AI technology available.